If you’re running a small manufacturing business, finding ways to boost output without breaking the bank is key. Cobots, or collaborative robots, are a smart choice for many in this spot. This buyer guide looks at the best cobots for small manufacturers in 2025, helping you pick the right one for your needs. Whether you’re searching for the best cobot for small factory setups or affordable cobots for SMEs, we’ll cover the basics, top picks, and tips to get started. As a collaborative robot buyer guide 2025, this post aims to give you clear, useful info based on current market options.

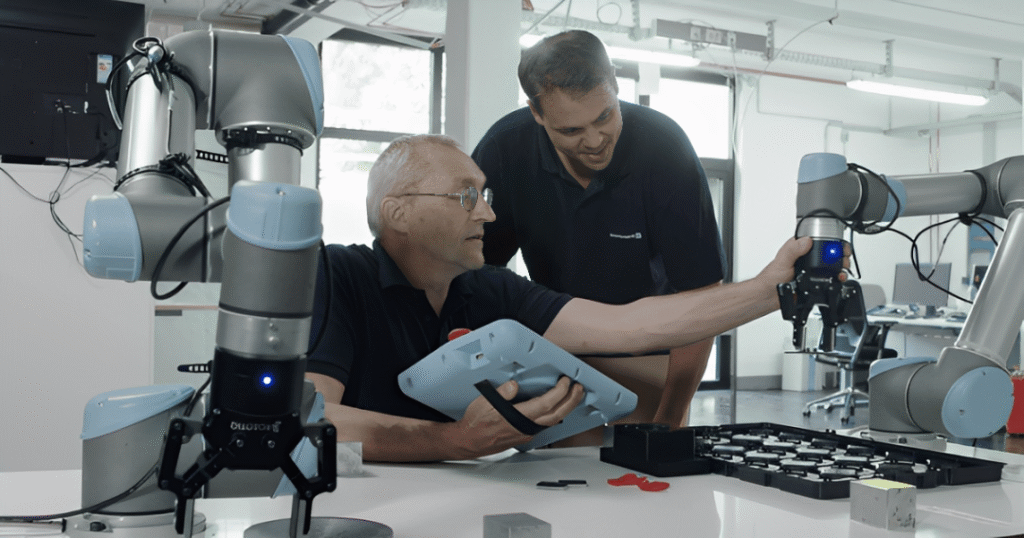

Cobots work side by side with people, handling repeated tasks like picking parts or packing items. They help small shops stay competitive by cutting labor costs and improving safety. In 2025, more small businesses are turning to these tools as prices drop and tech gets better. Let’s break it down step by step.

What Are Cobots and Why Do They Matter for Small Manufacturers?

Cobots are robots built to team up with human workers in shared spaces. Unlike old-school industrial robots that need cages for safety, cobots have sensors to stop if they touch a person. This makes them fit well in tight factory floors common in small operations.

For small manufacturers, cobots solve big problems like worker shortages and rising costs. They take on boring jobs, freeing up staff for more skilled work. A report shows the global cobot market is set to grow from $1.42 billion in 2025 to $3.38 billion by 2030, with a yearly growth rate of 18.9%. This growth comes from small businesses jumping in, as cobots become easier to use and cheaper.

Benefits for Small Businesses

One main plus is cost savings. Traditional robots can cost hundreds of thousands, but cobots start at around $20,000 to $50,000, making them affordable cobots for SMEs. They pay for themselves fast—often in under a year—through higher output and fewer mistakes.

Safety is another win. Cobots have built-in limits on force and speed, so they won’t hurt workers. This cuts down on accidents in small factories where space is limited. Plus, they’re flexible. You can move them between tasks, like from assembly to packaging, without much hassle.

For example, in a small metal shop, a cobot can tend machines all day, letting workers focus on quality checks. This boosts overall flow without adding staff.

Differences from Traditional Robots

Traditional robots are big, fast, and strong but need separate areas to run safely. They’re great for large car plants but overkill for small manufacturers. Cobots are smaller, slower, and designed for teamwork. They don’t require expert programmers; many use simple apps or hand-guiding to teach them jobs.

In short, if your factory is small and you want quick setup without big changes, cobots are the way to go.

Key Factors to Consider When Buying a Cobot in 2025

Picking the right cobot means looking at your specific needs. This collaborative robot buyer guide 2025 highlights what to check before buying.

Payload and Reach

Payload is how much weight the cobot can lift, from 3kg for light tasks to 30kg for heavier ones. Reach is the arm’s length, usually 500mm to 1700mm. For small factories, aim for 5-10kg payload and 800-1300mm reach to handle common jobs like part sorting.

If you’re in electronics, a low-payload model works. For welding or palletizing, go higher.

Safety Features

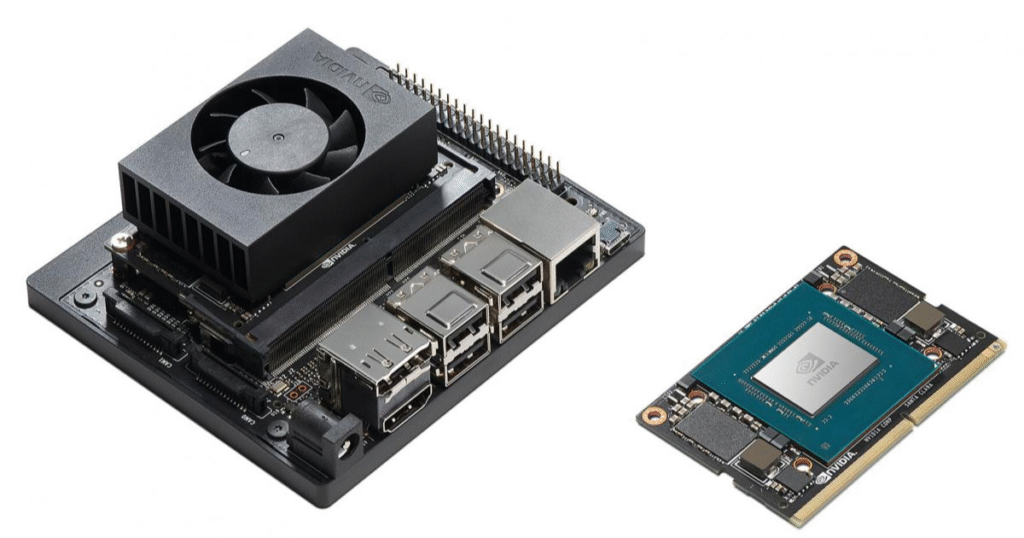

All cobots meet basic safety standards, but look for extras like collision detection and speed monitoring. In 2025, many include AI to predict risks. Test how it reacts in your space to ensure it fits with your team.

Ease of Use and Programming

For small manufacturers without robot experts, pick models with user-friendly interfaces. Hand-guiding lets you show the cobot a task by moving its arm. Apps and no-code software make setup fast—some take just hours.

Brands like Universal Robots offer plug-and-play options, ideal for SMEs.

Cost and ROI

Prices range from $15,000 for basic models to $60,000+ for advanced ones. Add costs for grippers, stands, and training. ROI comes quick: one study notes an average payback of 195 days for small businesses.

Factor in ongoing costs like maintenance. Affordable cobots for SMEs often have low upkeep, helping budgets stay in check.

Integration and Compatibility

Check if the cobot works with your machines. Look for open platforms that connect to tools like conveyors or vision systems. For small factories, easy integration means less downtime.

Ask vendors for demos or trials to see it in action.

Top Cobots for Small Manufacturers in 2025

Based on reviews and specs, here are standout models. We picked these for their fit in small setups, focusing on reliability, price, and features. This list draws from comparisons of over 280 cobots.

Universal Robots UR3e: Best for Precision Tasks

The UR3e is a compact 6-axis cobot with 3kg payload and 500mm reach. It’s great for small factories doing assembly or testing. Price: around $25,000.

Pros: Easy to program with a teach pendant; lightweight at 11kg for easy moves; certified safe.

Cons: Limited to light loads; not for heavy lifting.

Use case: In a small electronics plant, it picks tiny parts accurately, boosting speed by 30%.

Universal Robots UR20: Best for Heavy Lifting

With 20kg payload and 1750mm reach, the UR20 handles bigger jobs like palletizing. It’s priced at about $45,000.

Pros: Strong yet safe; integrates with many tools; fast setup.

Cons: Higher cost; needs more space.

For small manufacturers in packaging, it’s a top pick, as it works non-stop without fatigue.

FANUC CRX-10iA: Best for Durability

FANUC’s CRX-10iA offers 10kg payload and 1249mm reach. It’s built tough for factory floors. Cost: $35,000-$40,000.

Pros: Reliable from a big brand; tablet programming; IP67 rating for dust/water.

Cons: Slightly steeper learning curve.

Ideal for small metal shops tending CNC machines, where it loads parts safely next to workers.

ABB GoFa CRB 15000: Best for Speed

This 5kg payload cobot reaches 950mm and moves at 2.2m/s. Price: around $30,000.

Pros: Fast and precise; wizard-based setup; good for mixed tasks.

Cons: Less payload than some rivals.

In food processing small factories, it handles packing quickly, improving line efficiency.

Doosan Robotics M1013: Best for Versatility

With 10kg payload and 1300mm reach, it’s flexible for various jobs. Cost: $25,000-$35,000, making it one of the affordable cobots for SMEs.

Pros: Multiple safety modes; easy teaching; works with many end-tools.

Cons: Bulkier design.

Suited for small auto parts makers, switching between welding and inspection.

Techman Robot TM5-700: Best for Vision Integration

Payload 6kg, reach 700mm. Includes built-in camera. Price: $30,000.

Pros: Smart vision for quality checks; compact for tight spaces; user-friendly.

Cons: Slower for heavy tasks.

Great for small labs or factories needing inspection, like checking product flaws.

Productive Robotics OB7: Best for Simple Tasks

7kg payload, 1000mm reach. Designed for easy use in small spaces. Cost: $20,000-$25,000.

Pros: No programming needed—teach by hand; mobile base option; low price.

Cons: Basic features compared to others.

Perfect as the best cobot for small factory starters, handling machine loading or sorting.

Budget Options: Elephant Robotics myCobot 320

For under $5,000, this 3kg payload arm is entry-level. Reach: 320mm.

Pros: Very cheap; open-source; good for testing.

Cons: Limited power; not for production-scale.

Affordable cobots for SMEs just starting out.

Dorna Robotics 2 Series

Around $10,000, 5kg payload, 600mm reach.

Pros: Fast speed; precise; easy software.

Cons: Newer brand, less support.

Fits small workshops for pick-and-place.

Han’s Robot Elfin Series

5-15kg payloads, prices from $15,000.

Pros: Good value; reliable; various sizes.

Cons: May need custom tweaks.

Strong choice for SMEs in assembly.

These models cover a range, from basic to advanced. Compare based on your tasks—for instance, if space is tight, go compact like UR3e.

Affordable Cobots for SMEs

Small businesses often need options that won’t strain budgets. Affordable cobots for SMEs start at $15,000 and offer solid performance. Models like the AUBO series or Shandong Gaochuang FR20 provide value, with prices around $3,500 for basic setups.

The igus Low Cost Automation line targets SMEs with arms under $10,000, focusing on long life and simple use. They’re great for testing automation without big risks.

For welding, Standard Bots RO1 is affordable at $25,000-$35,000, with quick ROI for small shops.

When shopping, look for packages including grippers to keep total costs low. Many vendors offer financing, making these accessible.

How to Implement Cobots in Your Small Factory

Getting a cobot running is straightforward, but plan well.

Step 1: Assess Your Needs

List tasks like repetitive lifting or inspection. Measure space and power needs.

Step 2: Choose and Buy

Use this guide to pick. Test demos—many brands offer trials.

Step 3: Setup and Training

Install takes a day. Train staff with online videos or vendor sessions. No experts needed.

Step 4: Integrate and Monitor

Connect to machines. Start slow, watch performance, tweak as needed.

Step 5: Scale Up

Once one works, add more for other lines.

Tips: Start small to build confidence. Focus on high-impact tasks for fast wins.

Case Studies: Real-World Wins for Small Manufacturers

In one small welding shop, adding a FANUC CRX cut setup time and boosted output by 40%. Workers now handle creative parts, improving job satisfaction.

A packaging firm used UR20 for palletizing, reducing errors and labor costs. Payback in 6 months.

For SMEs, cobots like OB7 helped a metal fabricator automate tending, freeing staff for growth.

These show how cobots drive real gains.

Future Trends in Cobots for 2025 and Beyond

In 2025, cobots get smarter with AI for better task learning. Mobile bases let them move around factories.

Sectors like logistics and healthcare push adoption, but manufacturing leads.

Expect lower prices and more plug-ins for tools. For small manufacturers, this means easier entry.

Read more informational and interesting blogs visit our website Lidarmos

Conclusion

This buyer guide wraps up the best cobots for small manufacturers in 2025. From the versatile UR series to affordable picks like myCobot, options suit every budget and need. As affordable cobots for SMEs become common, now’s the time to automate. Pick based on your tasks, test thoroughly, and watch your factory improve. If you’re eyeing the best cobot for small factory use, start with a demo today.